Application and advantages of rubber sheets in the construction industry

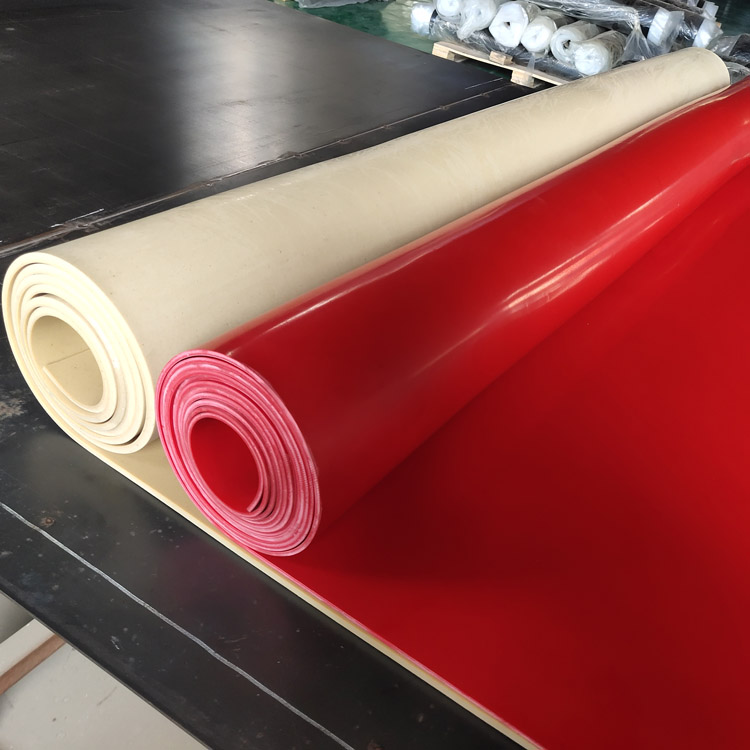

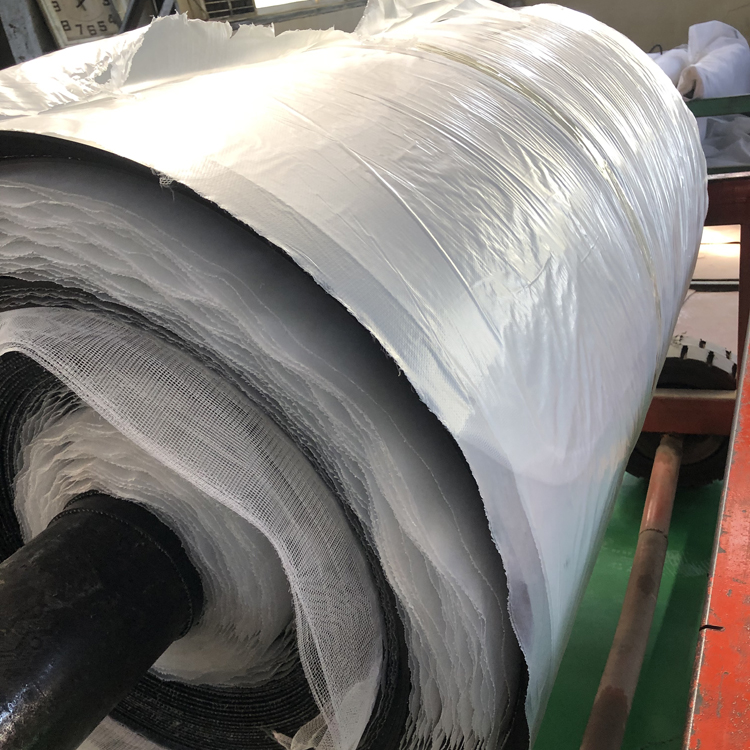

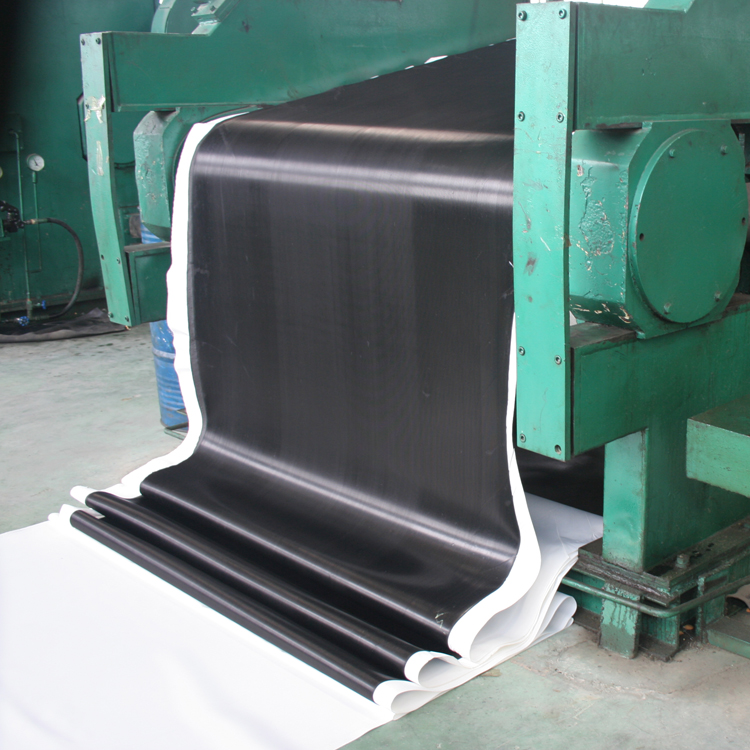

Rubber sheets are widely used in the construction industry, mainly for waterproofing, sound insulation, shock absorption and other aspects. With its excellent elasticity, wear resistance and corrosion resistance, rubber sheets provide many innovative solutions for the construction industry.

1. Waterproof application

Rubber sheets are often used in waterproof projects such as roofs, basements and bathrooms of buildings due to their good waterproof performance. The following are the specific advantages of rubber sheets in waterproof applications:

Durability: Rubber sheets have high tensile strength and elongation, and can withstand various deformations of building structures without breaking, ensuring long-term and effective waterproofing effects.

Weather resistance: In particular, EPDM rubber sheets have strong UV and ozone resistance, and are suitable for exposed roof waterproofing layers.

Easy construction: Rubber sheets are light in weight and easy to construct. They can be laid by welding or gluing, which greatly improves construction efficiency.

2. Sound insulation application

In modern buildings, sound insulation performance has become one of the important criteria for measuring building quality. Rubber sheets are often used in sound insulation layers of walls, floors and ceilings due to their excellent sound insulation effects. Its advantages include:

Sound absorption performance: The high density of rubber sheets can effectively absorb sound waves and reduce noise conduction.

Shock absorption performance: Rubber sheets have good elasticity, can absorb and attenuate vibration waves, and reduce the propagation of sound.

3. Shock absorption application

When buildings are subjected to external vibration or impact, rubber sheets as shock-absorbing materials can provide good protection. Specific applications include:

Foundation shock absorption: Laying rubber sheets in the foundation of the building can effectively buffer the vibration caused by earthquakes or foundation settlement and protect the stability of the building structure.

Equipment shock absorption: Laying rubber sheets under large equipment such as air conditioners and generators can reduce the vibration transmission during equipment operation, reduce noise, and extend the life of the equipment.

4. Other applications

Rubber sheets have many other applications in the construction industry, such as:

Floor padding: Laying rubber sheets under the floor can increase the elasticity and comfort of the floor and reduce noise when walking.

Wall moisture-proof layer: Rubber sheets have good moisture-proof performance and are often used for moisture-proof treatment of walls in basements and humid areas to prevent mold and corrosion.

In general, the application of rubber sheets in the construction industry is of great significance. It not only improves the comfort and durability of buildings, but also provides reliable material support for green buildings and sustainable development. With the advancement of science and technology and changes in construction needs, the application scope and performance of rubber sheets will continue to expand and improve.

1. Waterproof application

Rubber sheets are often used in waterproof projects such as roofs, basements and bathrooms of buildings due to their good waterproof performance. The following are the specific advantages of rubber sheets in waterproof applications:

Durability: Rubber sheets have high tensile strength and elongation, and can withstand various deformations of building structures without breaking, ensuring long-term and effective waterproofing effects.

Weather resistance: In particular, EPDM rubber sheets have strong UV and ozone resistance, and are suitable for exposed roof waterproofing layers.

Easy construction: Rubber sheets are light in weight and easy to construct. They can be laid by welding or gluing, which greatly improves construction efficiency.

2. Sound insulation application

In modern buildings, sound insulation performance has become one of the important criteria for measuring building quality. Rubber sheets are often used in sound insulation layers of walls, floors and ceilings due to their excellent sound insulation effects. Its advantages include:

Sound absorption performance: The high density of rubber sheets can effectively absorb sound waves and reduce noise conduction.

Shock absorption performance: Rubber sheets have good elasticity, can absorb and attenuate vibration waves, and reduce the propagation of sound.

3. Shock absorption application

When buildings are subjected to external vibration or impact, rubber sheets as shock-absorbing materials can provide good protection. Specific applications include:

Foundation shock absorption: Laying rubber sheets in the foundation of the building can effectively buffer the vibration caused by earthquakes or foundation settlement and protect the stability of the building structure.

Equipment shock absorption: Laying rubber sheets under large equipment such as air conditioners and generators can reduce the vibration transmission during equipment operation, reduce noise, and extend the life of the equipment.

4. Other applications

Rubber sheets have many other applications in the construction industry, such as:

Floor padding: Laying rubber sheets under the floor can increase the elasticity and comfort of the floor and reduce noise when walking.

Wall moisture-proof layer: Rubber sheets have good moisture-proof performance and are often used for moisture-proof treatment of walls in basements and humid areas to prevent mold and corrosion.

In general, the application of rubber sheets in the construction industry is of great significance. It not only improves the comfort and durability of buildings, but also provides reliable material support for green buildings and sustainable development. With the advancement of science and technology and changes in construction needs, the application scope and performance of rubber sheets will continue to expand and improve.