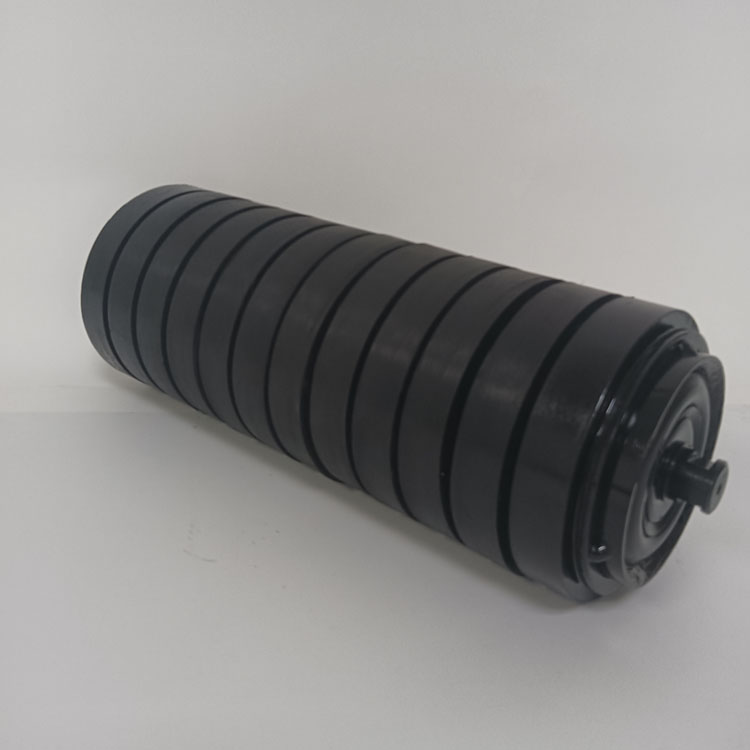

Impact Idler Roller

Description

Impact idler Roller, also known as buffer idler, is a specially designed roller primarily used at material receiving points of belt conveyors to cushion the impact of material loading onto the conveyor belt. Its core components include the roller, bearings, and outer shell, with the outer shell protecting the internal roller and bearings to ensure smooth operation.

The principle of Impact idler Rollers mainly relies on the absorption and cushioning of impact forces by internal components such as springs and shock-absorbing rubber. When material falls onto the Impact idler Roller from above, the springs and shock-absorbing rubber absorb a portion of the impact force, mitigating the impact on the conveyor belt. Subsequently, the absorbed energy is gradually released, transferring the impact force to adjacent idlers or the conveyor belt.

Impact idler Rollers offer several advantages, including:

1.Corrosion resistance: The Impact idler Roller itself has toughness over ten times that of ordinary metals, with a lifespan five times longer than traditional roller shoes. It is corrosion-resistant, flame-retardant, antistatic, and lightweight. The roller body and sealing parts are made of polymer materials, providing corrosion resistance. When used in corrosive environments, the lifespan can exceed five times that of ordinary rollers.

2.Wear resistance: The roller body of Impact idler Rollers is made of special polymer materials with mechanical properties similar to bronze, offering excellent wear resistance and good self-lubricating properties without damaging the conveyor belt.

3.Cushioning effect: Impact idler Rollers effectively reduce material impact and vibration on the conveyor belt, protecting the belt and extending its lifespan.

Additionally, Impact idler Rollers are available in various types, such as drum-type Impact idler Rollers, tapered roller Impact idler Rollers, and belt-type Impact idler Rollers, to meet different application scenarios and requirements.

In practical applications, proper installation and adjustment of Impact idler Rollers are crucial to ensure normal operation and achieve the desired cushioning effect. When purchasing, attention should also be paid to parameters such as radial runout, flexibility, dust-proofing, waterproofing, axial load-bearing capacity, and impact resistance of the idlers.

Table 1. Radial Runout

|

Impact Ring Dia.

(mm)

|

Inner Tube Dia.

(mm)

|

Impact idler length

(mm)

|

|||

| <460 | 460~950 | 950~1600 | >1600 | ||

| φ89 | φ60 | 0.5 | 0.7 | 1.3 | 1.5 |

| φ108 | φ75.5 | 0.5 | 0.7 | 1.3 | 1.5 |

Table 2. Rotational Resistance

| Impact Ring Dia.(mm) | Inner Tube Dia.(mm) | idler length(mm) | Rotational Resistance (N) |

| φ89 | φ60 | ≤460 | 2.0 |

| >460 | 2.5 | ||

| φ108 | φ75.5 | ≤460 | 2.0 |

| >460 | 2.5 |

Table 3. Axial Load

| Impact Ring Dia.(mm) | idler length(mm) | Axial Load(kN) |

| φ89-φ108 | φ60-75.5 | 10 |

FAQ:

1. What are Impact Idler Roller?

Impcact Idler Roller are specially designed rollers that are positioned at strategic points along the conveyor system to absorb the impact of heavy loads. They help to reduce the shock and vibration caused by the impact, protecting the conveyor belt and other components from damage.

2. How do environmental conditions, such as temperature and moisture, affect the performance of Impact Idler Roller?

such as temperature and moisture levels, is crucial for ensuring optimal performance and longevity of Impact Idler Roller in conveyor systems. Regular inspection and maintenance are also necessary to identify and address any issues caused by environmental factors.

3. Types of Impcact Idler Roller?

There are several types of Impcact Idler Roller available, including:

A.Rubber Impact Idlers: These idlers have a rubber coating that helps to absorb impact and reduce the risk of belt damage.

B.Steel Impact Idlers: These idlers are made from steel and are designed to provide maximum impact resistance and durability.

Related Products

Rubber Disc Return Idler

Carrying Idler Roller

Impact Idler Roller

HDPE Idler Roller