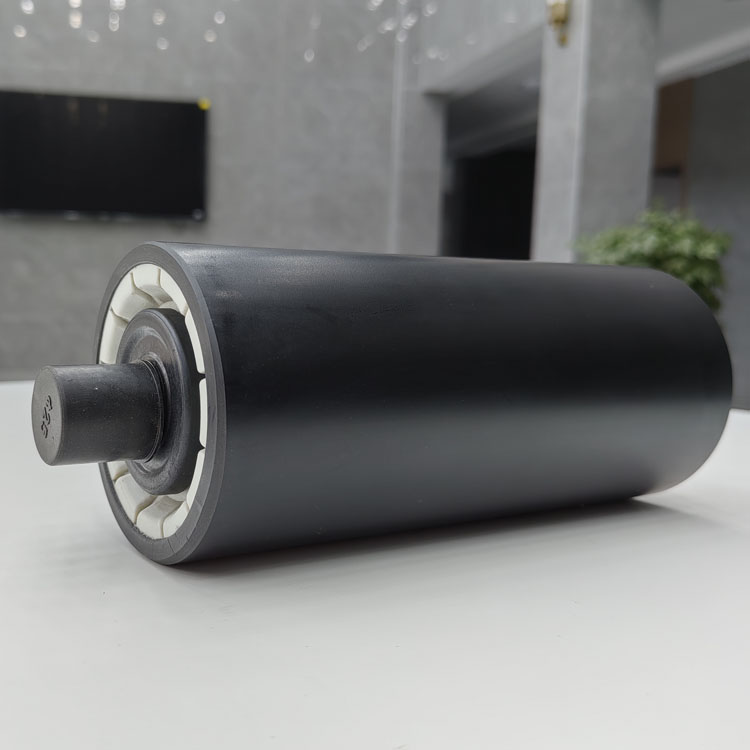

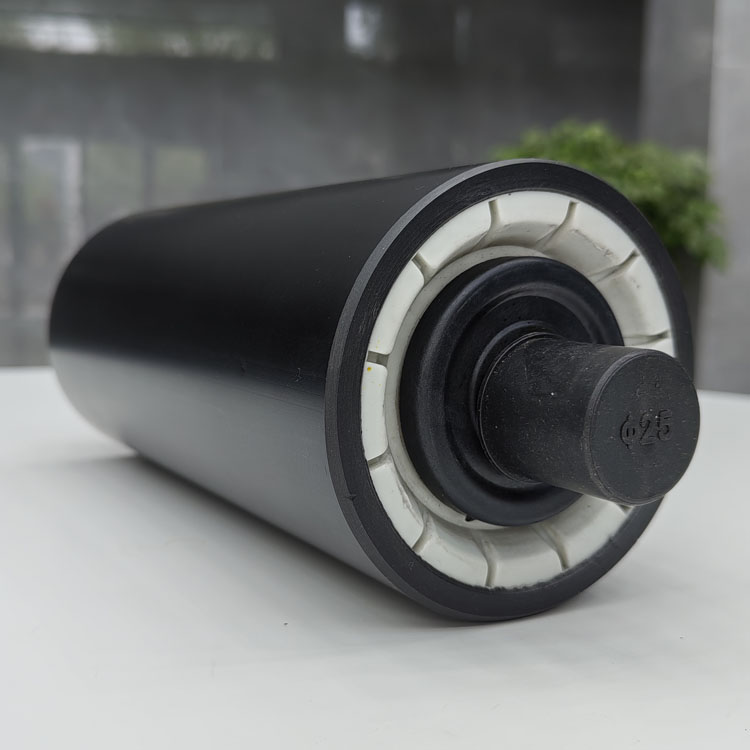

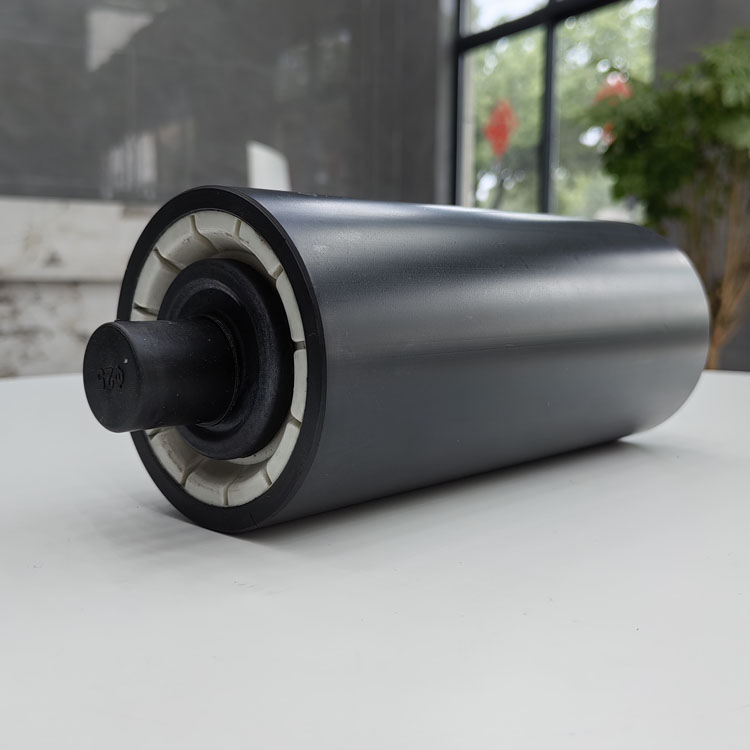

HDPE Idler Roller

Description

The HDPE Idler Roller are rollers made of High Density Polyethylene (HDPE) material. It has the following features and advantages:

1. Wear resistance: HDPE Idler Roller have excellent wear resistance and can maintain stable performance under long-term high-intensity use, effectively extending service life and reducing maintenance costs.

2.Chemical corrosion resistance: The polymer polyethylene material has excellent chemical corrosion resistance and can show stable and reliable performance in acid, alkali and humid environments.

Impact resistance and scratch resistance: HDPE Idler Roller also have good impact resistance and scratch resistance, which can effectively protect conveyed materials and conveying system equipment in various complex working conditions.

2. Environmental protection: HDPE material itself is non-toxic, odorless and meets environmental protection requirements. It can be used in special industries such as food and medicine to ensure the safety and hygiene of items.

The HDPE Idler Roller can not only be used for the transportation and storage of conventional materials, but are also widely used in special industries such as medicine to ensure the safety and hygiene of items. The HDPE Idler Roller also show their unique advantages and can withstand large cargo loads and ensure efficient operation.

In addition, after years of practice and exploration, the production process of the HDPE Idler Roller has been gradually improved and optimized to provide high-quality, high-performance products.

Standard: CEMA, SABS, DIN, JIS, AS standards are available, as well as OEM service.

|

Belt

Width

|

Type | Dimension | Bearing | |||||||

| ΦD | ① d | L1 | L2 | A | K | B | W | |||

| 400 | CR-400 | Φ89.1 | Φ20 | 145 | 175 | 153 | 8 | 11 | 14 | 6204 2RS |

| 450 | CR-450 | 165 | 195 | 173 | ||||||

| 500 | CR-500 | 180 | 210 | 188 | ||||||

| 600 | CR-600-1 | 210 | 240 | 218 | ||||||

| 650 | CR-650 | 225 | 255 | 233 | ||||||

| 600 | CR-600-2 | Φ114.3 | 210 | 240 | 218 | |||||

| 750 | CR-750 | 265 | 295 | 273 | ||||||

| 800 | CR-800 | 275 | 305 | 283 | ||||||

| 900 | CR-900 | 315 | 345 | 323 | ||||||

| 1000 | CR-1000 | Φ139.8 | Φ 25 | 350 | 390 | 360 | 11 | 15 | 18 | 6205 2RS |

| 1050 | CR-1050 | 370 | 410 | 380 | ||||||

| 1200 | CR-1200 | 420 | 460 | 430 | ||||||

| 1400 | CR-1400 | Φ165.2 | Φ30 | 500 | 540 | 510 | 22 | 6206 2RS | ||

| 1600 | CR-1600 | 580 | 620 | 590 | ||||||

| 1800 | CR-1800 | Φ 35 | 650 | 690 | 660 | 25 | 6207 2RS | |||

| 2000 | CR-2000 | 730 | 770 | 740 | ||||||

| 2200 | CR-2200 | Φ 40 | 800 | 840 | 810 | 31 | 6208 2RS | |||

| 2400 | CR-2400 | 880 | 920 | 890 | ||||||

Related Products

Rubber Disc Return Idler

Carrying Idler Roller

Impact Idler Roller

HDPE Idler Roller