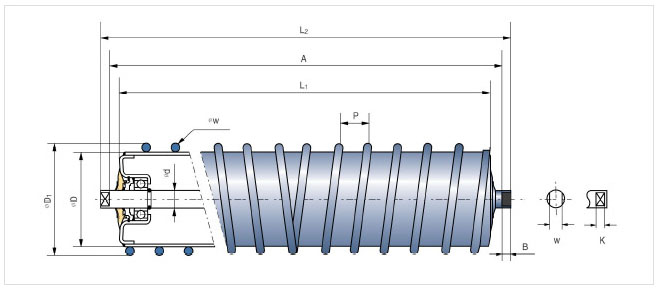

Steel Screw Self-Cleaning Idler Roller

Description

The Steel Screw Self-cleaning idler roller is a specially designed roller that is mainly used to clean materials attached to the load-bearing surface of the conveyor belt. Its working principle is to allow foreign objects to naturally break away from the working surface of the tape along the trajectory of the steel spiral, which is similar to the function of a cleaner.

The Steel Screw Self-cleaning idler roller usually consist of spiral shafts, housings, brakes, bearings and other components. When working, the material reaches the spiral roller through the conveyor belt or roller. The spiral shaft lifts the material upward and pushes it to the required height to complete the cleaning process of the material. This kind of roller is usually designed as the set of lower rollers closest to the conveyor head roller to more effectively clean the material on the conveyor belt.

In addition, there is a two-way spiral cleaning roller, which is a device that can quickly clean garbage and dust on the road. The roller has the function of forward and reverse rotation, which can quickly remove garbage and dust. At the same time, the surface of the roller is made of special material, which is not easy to adhere to garbage and dust. It can automatically clean the surface and maintain the cleaning effect. This kind of roller is suitable for cleaning in various environments such as urban roads, squares, airports, docks, and industrial sites.

|

Type |

BeltWidth(mm) |

Diameter

(mm)

|

Shaft

Dia.

|

Length(mm) |

|

Return Roller |

||||

|

BNR/1 |

500,650,800,100,1200,1400 |

89 |

20 |

600,750,950,1150,1400,1600 |

|

500,650,800,1000,1200 |

108 |

600,750,950,1150,1400 |

||

|

500,650,800,1000,1200,1400 |

133 |

600,750,950 |

||

|

BNR/2 |

500,650,800,1000,1200,1400,1600 |

89 |

25 |

600,750,950,1150,1400,1600,1800 |

|

500,650,800,1000,1200,1400,1600 |

108 |

600,750,950,1150,1400,1600,1800 |

||

|

650,800,1000,1200,1400,1600,1800,2000 |

133 |

750,950,1150,1400,1600,1800,2000,2200 |

||

|

1000,1200,1400,1600,1800 |

159 |

1150,1400,1600,1800,2000 |

||

|

BNR/3 |

500,650,800,1000,1200,1400,1600 |

89 |

25 |

1150,1400,1600,1800 |

|

500,650,800,1000,1200,1400,1600 |

108 |

1150,1400,1600,1800 |

||

|

650,800,1000,1200,1400,1600,1800,2000 |

133 |

1150,1400,1600,1800,2000,2200 |

||

|

1000,1200,1400,1600,1800 |

159 |

1150,1400,1600,1800,2000 |

||

|

BNR/4 |

1000,1200,1400,1600 |

89 |

30 |

1150,1400,1600,1800 |

|

1000,1200,1400,1600 |

108 |

1150,1400,1600,1800 |

||

|

1000,1200,1400,1600,1800,2000 |

133 |

1150,1400,1600,1800,2000,2200 |

||

|

1000,1200,1400,1600,1800 |

159 |

1150,1400,1600,1800,2000 |

||

|

BNR/5 |

1000,1200,1400,1600,1800,2000 |

133 |

1150,1400,1600,1800,2000,2200 |

|

|

1000,1200,1400,1600,1800 |

159 |

1150,1400,1600,1800,2000 |

||

|

BNR/6 |

1600,1800 |

159 |

40 |

1800,2000 |

Related Products

Rubber Disc Return Idler

Carrying Idler Roller

Impact Idler Roller

HDPE Idler Roller